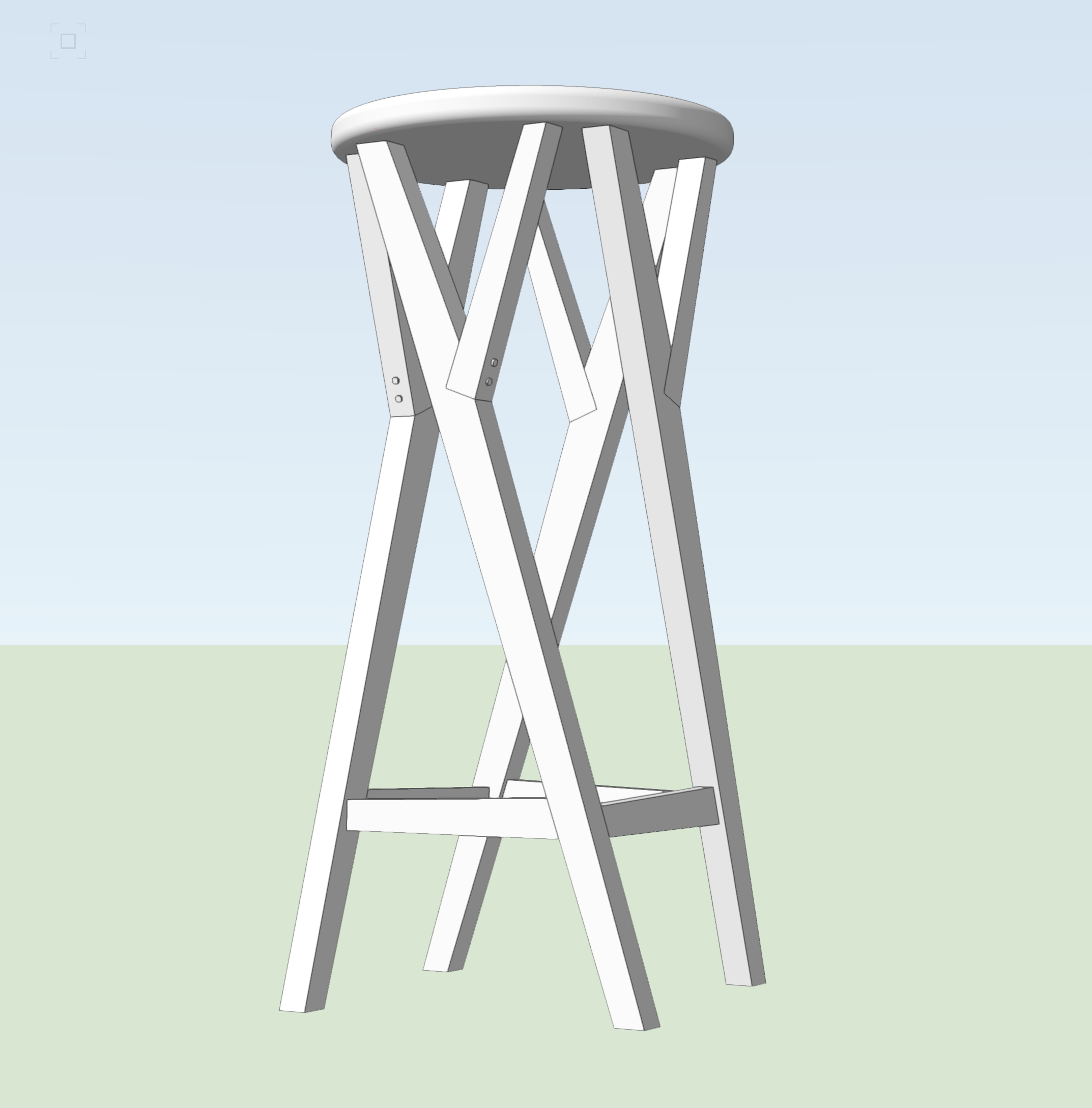

Stool

Perhaps in preparation for making a more ambitious piece of furniture and perhaps to test my skills and limits I set out to make a stool – useful in the house or workshop. It has been an interesting project and as usual working the materials themselves is less difficult than designing an elegant piece of furniture. I have learnt why prototypes are so important as the tiniest tweaks of form make a lot of difference, restraint is everything. Designing in 3 dimensions on the computer certainly helps but it does not replace testing and testing again in real life.

Lessons?

Each leg assembly is vertical in one plane and at right angles to the next. It might have been more elegant (and of course geometrically more difficult to do) if they had splayed out, starting closer together at the top and becoming further apart at the base.

Although I set out to make the legs as thin and light as possible they are not as light as I had hoped – the oak is immensely strong so I should use smaller sections next time.

The seat has rounded top and bottom edges with the radii of the rounding resulting from available router bits. In hindsight the seat would have been more elegant if the edge had been one continuous half round or alternatively had sharper arises with little or no rounding. A friend had also suggested making the top of the seat a gentle convex, which would have been interesting and possibly more comfortable.